Tapio Aunio has acquired all shares of the Yudo Nordic Oy / Oinonen Tooling from Timo Oinonen and Birgitta Hendrell-Oinonen on August 31st, 2017. Read more..

Injection moulding

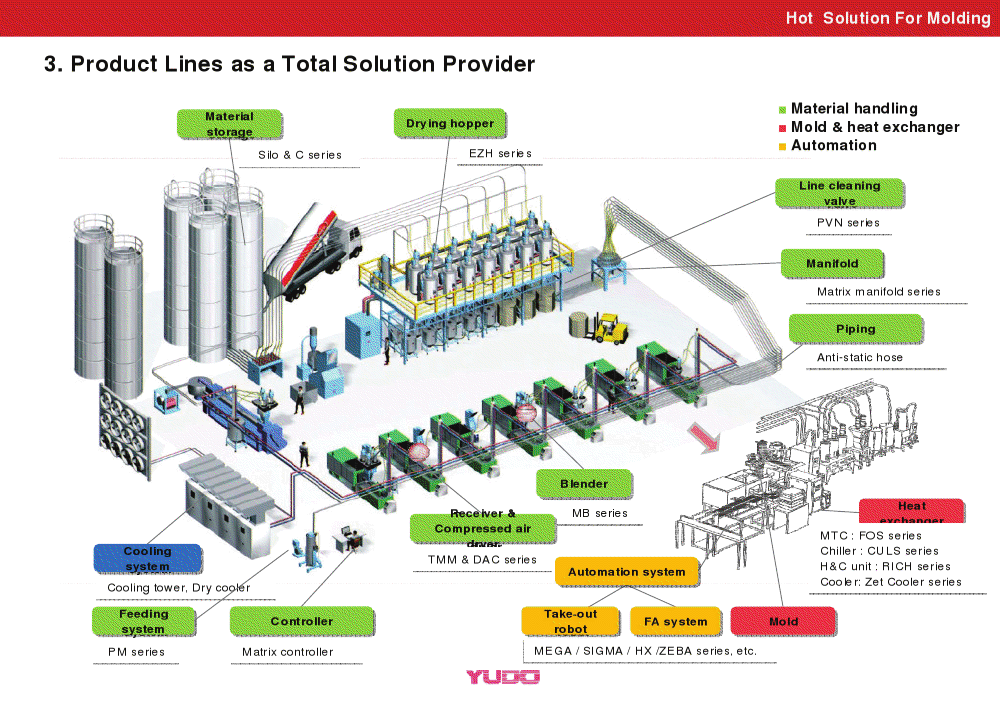

YUDO Group's subsidiary YUDO-SUNS can provide all necessary pre-processing equipment, dryers, and conveyors for raw materials, as well as temperature controlling equipment and coolers for tools and the necessary crushing mills for waste recycling.

Robots required for automation are manufactured at the YUDO-STAR factory with YUDO-SUNS having the overall responsibility for the system delivery.

YUDO-SUNS delivered all auxiliary equipment for the injection moulding factory shown in this picture.

EQUIPMENT FOR HANDLING RAW MATERIALS

(auto feeding system)

Vacuum pumps, bins, hoppers, bin vacuum pumps, piping components, manifolds, scales, volumetric dosing units, etc.

EZ-vacuum pump

Filter and vacuum pump

Storage bins

Hopper dryer, with air as the heating medium

MATRIX feed hoppers

DTM multi-hopper system

DW Howey desiccant dryer

D 800 P desiccant dryer unit

Compressed air dryer

JAWS 500 high speed granulator

Volumetric dosing unit

Automatic manifold for feeding raw material

MOULD TEMPERATURE CONTROLLERS AND COOLING SYSTEMS

(auxiliary equipment)

Mold temperature controllers

RICH steam temperature controller

CULS cooling system

Oil cooler